The Challenge

The Bottleneck Holding Back the Spirits Industry

Traditional multi-year production locks brands into speculative investments, slowing innovation and increasing the risk of inaccurate demand projections.

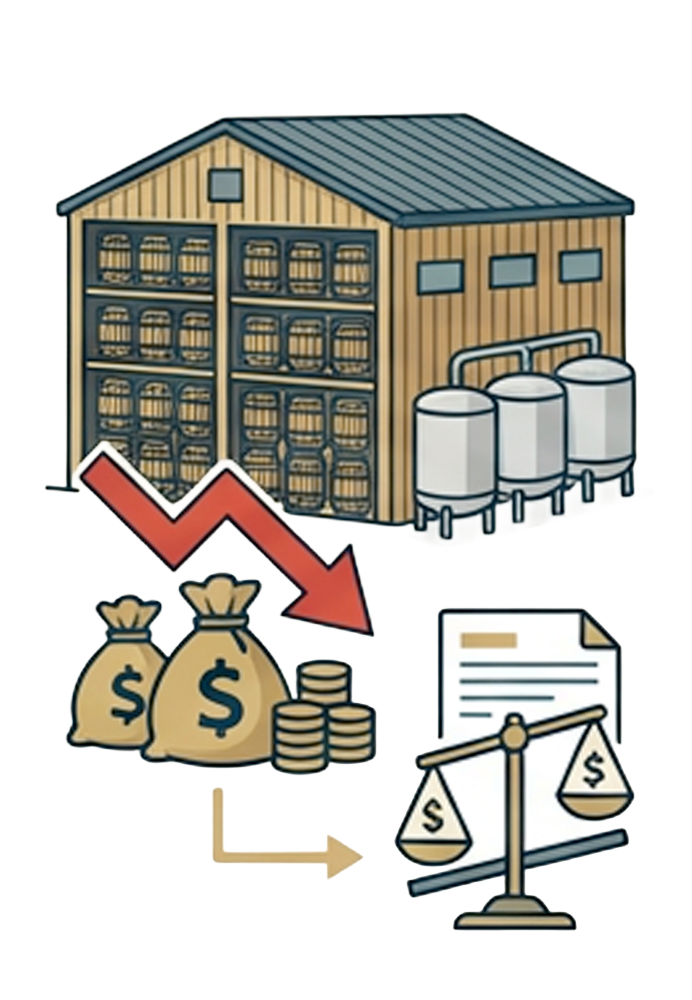

High Capital Costs

Resource-heavy barrel aging consumes significant wood and energy, raising environmental footprint and operational waste.

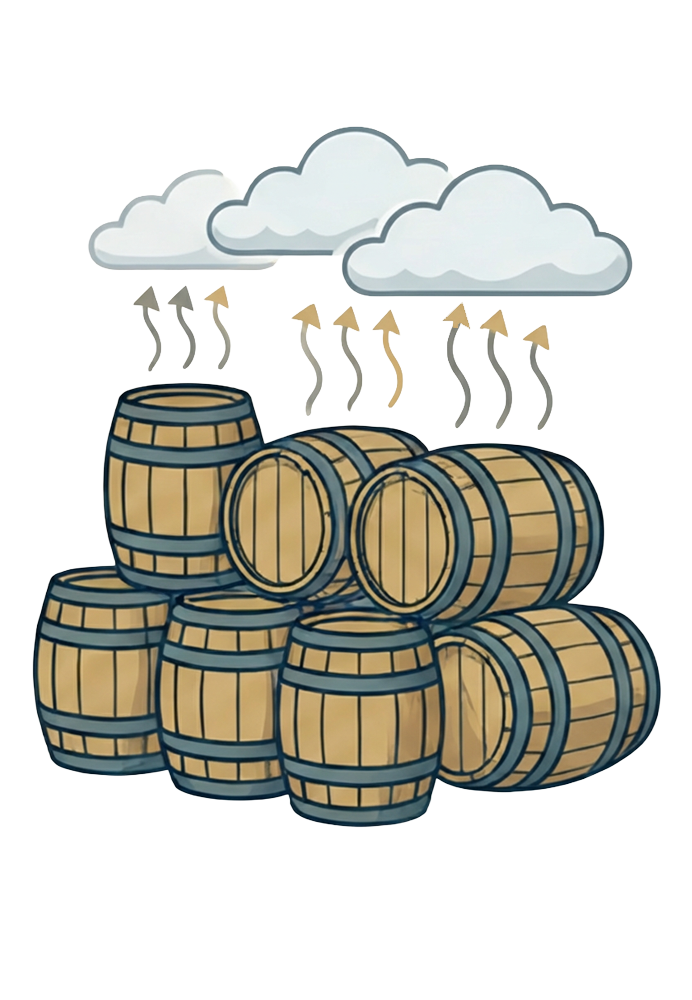

Evaporation Losses

No two barrels age alike—requiring blending to achieve consistent flavor profiles and stifling innovation.

Costly Environmental Impact

Cash sits idle for years in warehouses, tying up inventory, space, and growth capital.

Inconsistent Batch Results

Traditional aging surrenders 10–50% to the “angel’s share”, wasting valuable product in every batch.

The Solution

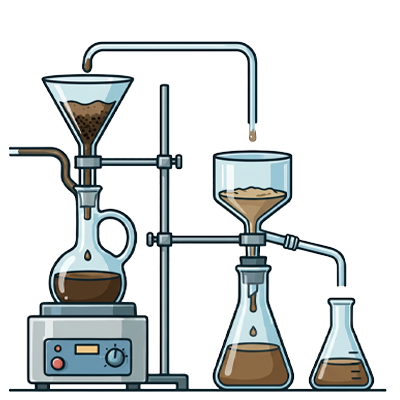

Our process accelerates natural maturation by precisely controlling how raw spirit, wood, water, and oxygen interact — the same elements behind every great barrel-aged spirit.

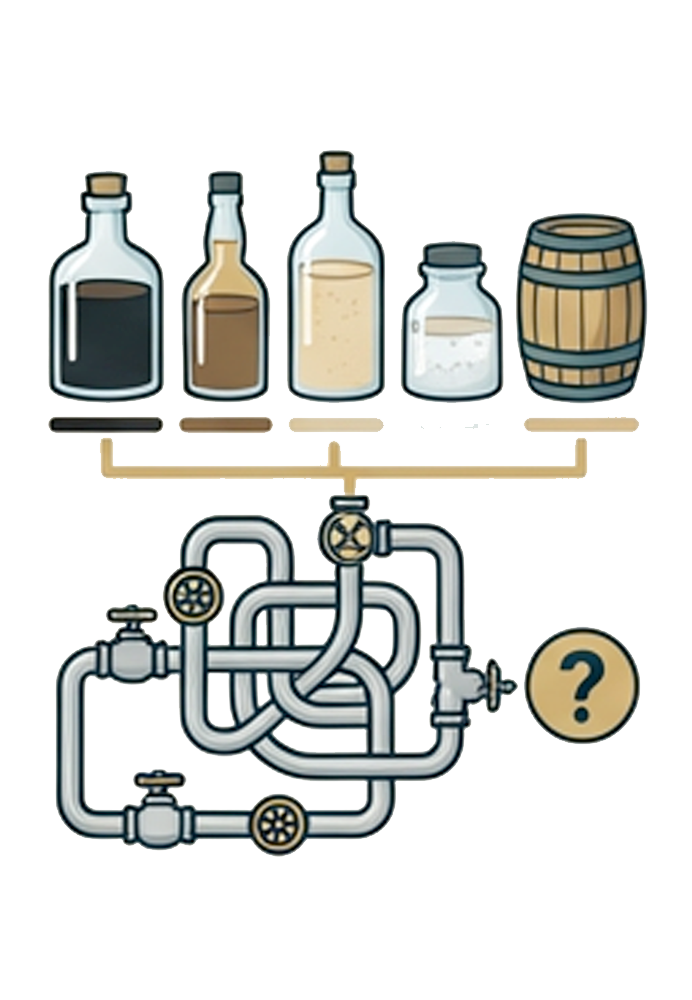

Refine

Reduce harsh congeners to produce a cleaner, smoother spirit.

Infuse

Extract flavor, color, and aroma from real oak.

Activate

Introduce oxygen to drive depth and smoothness.

Combine

Catalyze advanced reactions to create new and more complex aromas.

Better by every measure

Faster Production

Years --> Days

Lower Costs

Less overhead, waste, and inventory risk

Sustainable

91% less wood 93% less CO₂

Consistent Flavor

Repeatable profiles, no climate dependence

Pure Quality --> Agility

Fast product launches, rapid scaling

The Proof is in the Pour

Ameragave x Barrel RM

Founders Brett and Holly set out to create an additive-free premium agave spirit with a distinct, custom flavor, but traditional aging methods would demand massive budget and years of experimentation.

Ameragave launched Silver and Gold expressions in less than a year, which quickly garnered critical acclaim—including Double Golds and Best-in-Class awards from top spirits competitions.

Read the Ameragave Story